Training is THE hot topic in the appliance repair trade these days. Experienced techs want to up their troubleshooting game and keep up with the newer models, and many new folks are looking for training in a skilled trade so they can get a job or start a business. Manufacturers and multi-truck operations have an ongoing virtual manhunt for skilled appliance repair techs. But they just don't exist because new technicians are not entering the trade at the same rate as old servicers are retiring.

Here are some important questions you should ask about any technician training program you are considering investing your time and money in.

- Is the material up-to-date, especially regarding computerized control boards?

- Are the courses self-paced?

- Is the educational style engaging and varied?

- Is there a sequential order of instruction?

- Are there quizzes or other forms of evaluation to make sure you are learning the concepts?

- Is there a way to ask questions during the course as well as down the road?

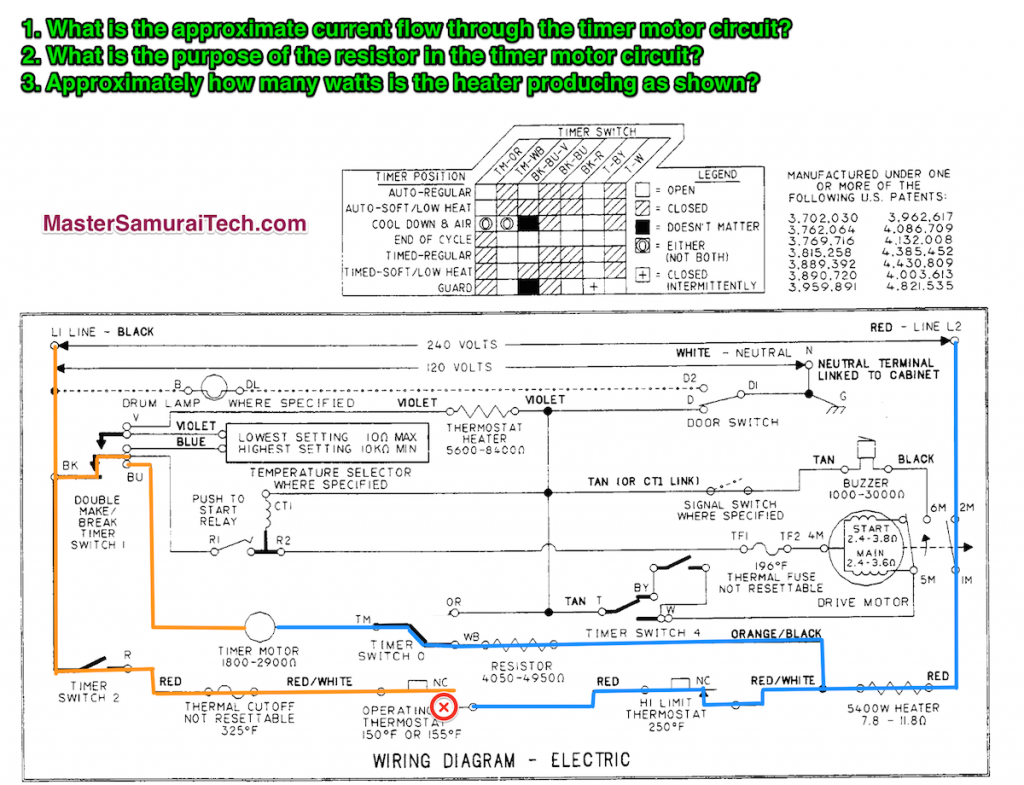

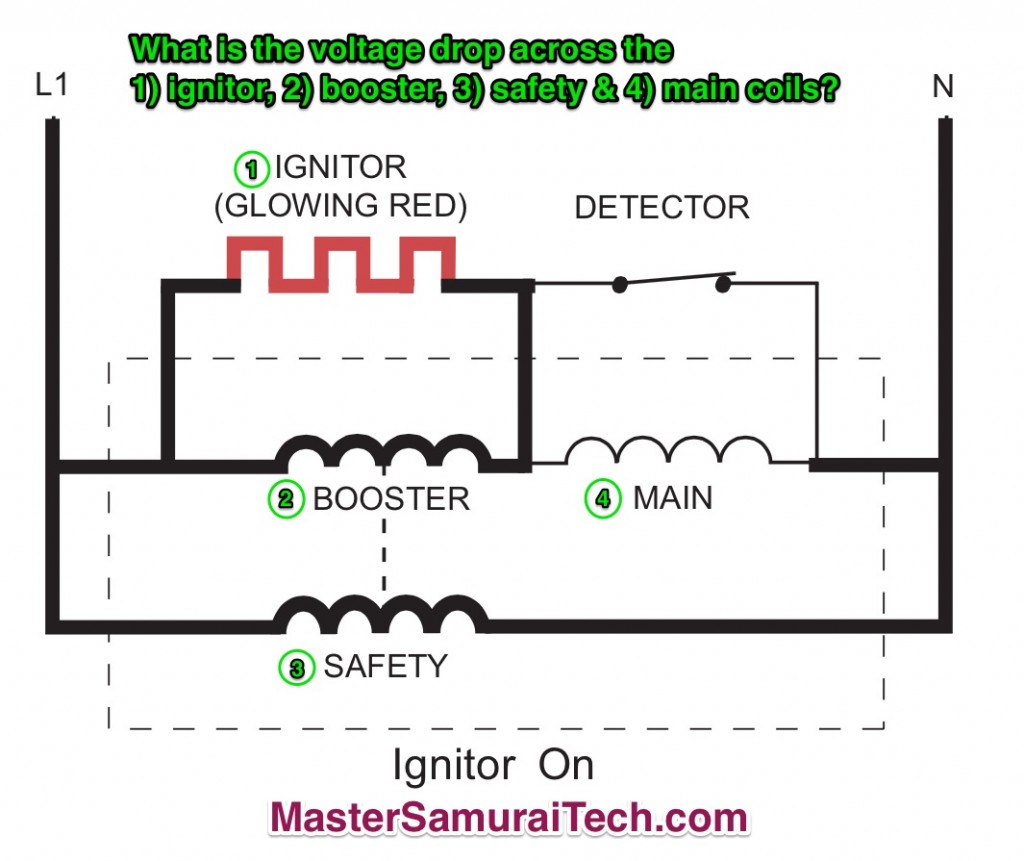

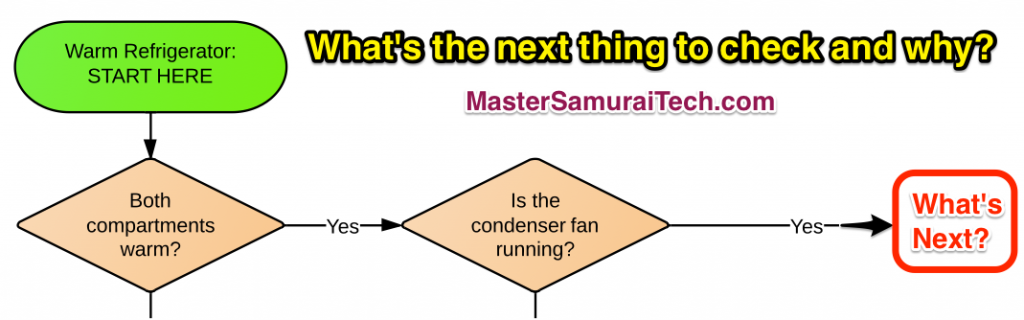

- Do you learn key troubleshooting skills using tech sheets and schematics?

- Does the school offer a meaningful certification from a verifiable master in the trade?

How can you tell if the school you are considering is up-to-date? Besides asking for the production date of the materials used in the class, you can ask questions such as:

- Do you teach using schematics to troubleshoot an appliance?

- Do you teach the technology used in current front-load washers and refrigerators, such as inverter-driven variable-speed motors?

And how do you choose between the various styles of appliance repair school that are out there? There are four basic types—

1. online training courses

2. in-person training schools

3. DVD and manual sets

4. correspondence courses

— and each has their strengths and weaknesses. The newest kid on the block, online training courses, was the format we found to be superior when we decided to create our training academy.

The Samurai Tech Academy Advantage...

vs. In-person training

Among the many advantages that the online Samurai Tech Academy has over in-person group training is that the STA allows students to go as fast or slow as they like, since the courses are self-paced. If a student needs more time to master a topic, they can go back and redo the lesson as much they want. The STA can be done whenever, wherever, no matter if you’re on the move or working from your house. In-person training obviously doesn't have such flexibility, and all the information has to be crammed into a very short period of time, making material retention difficult. Also, there are travel costs and time taken out from productive work days to attend the in-person training.

vs. DVDs and Manual sets

The online format allows us to keep the Samurai Tech Academy courses current and up to date with the latest technologies used in today’s appliances and doesn't flood our students with costly textbooks or DVDs, which can quickly get outdated. No one wants to pay for manuals or other materials that are so out of date that they're not even useful.

Many DVD-based programs do not have a specific sequence of instruction or testing, leaving it up to the student to figure it out. On the other hand, all the courses at the STA are carefully structured and organized to promote learning and material absorption.

Each course is broken up into small, digestible units, which are themselves made up of individual lessons. Our multimedia lessons use videos, text, diagrams, and audio to give an immersive, varied learning experience to help students better grasp the material. The lessons all end in quizzes so students can test and apply what they just learned and to further aid in retaining the information and determine any topics that need further review.

vs. Correspondence Courses

Some training courses out there still use only written materials and rely on instructor grading of materials. The STA’s online format allows for dynamic, up-to-date instruction and automatic grading of quizzes, so you determine your own pace.

Other Benefits

�Interactive Help

If a student has questions, I’ve got answers, and the online Student Forums are where that happens. It’s like a class discussion, but time-independent! Also, we hold weekly LIVE Office Hours for Academy students.

Cutting-edge Education from an Expert

As you can see by checking out my YouTube channel, I enjoy showing others how to hone their craft.

I’ve also realized something that needs to be emphasized in the appliance repair community: that being an excellent technician requires more than disassembly and parts-changing skills. You need a fundamental understanding of the electrical and mechanical workings of each machine, as well as the ability to use the technical information for any appliance (such as the schematic diagram) to formulate a troubleshooting strategy.

This is critically important if you want to deal with today’s modern appliances with confidence and profitably. I know that this is a weakness with many techs out there, which is why I put so much emphasis on teaching this skill in the Academy courses.

There are loads of resources online that tell you all you need to know about disassembly and parts-changing. These resources are either free or nearly free. You don’t need to pay for a course on this.

Spend your training money where it really counts on a program that will teach you to be a troubleshooting master. That’s exactly what we offer at the Samurai Tech Academy at MasterSamuraiTech.com.

Complete the Free Sample Course to get a foretaste of the empowering wisdom that awaits you!